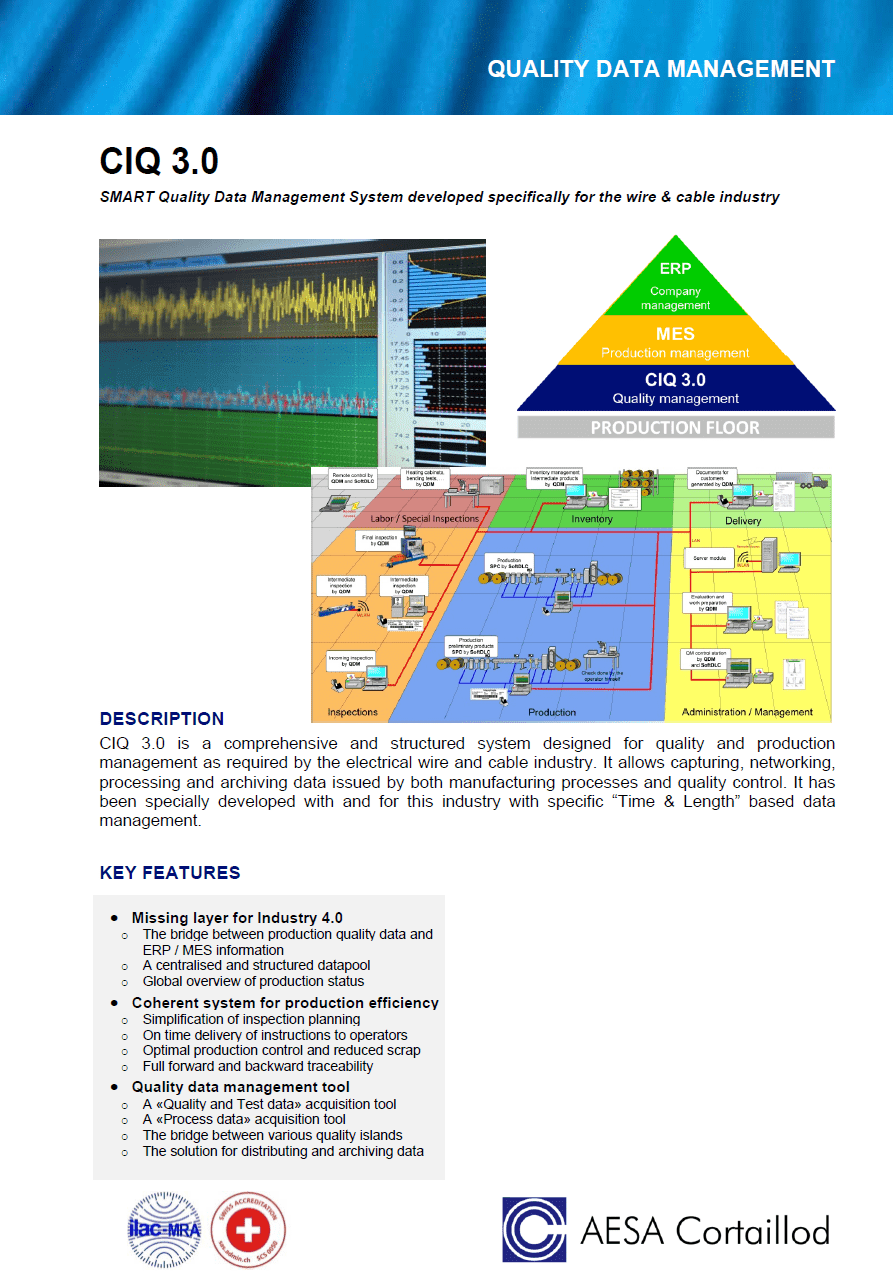

Data Management System

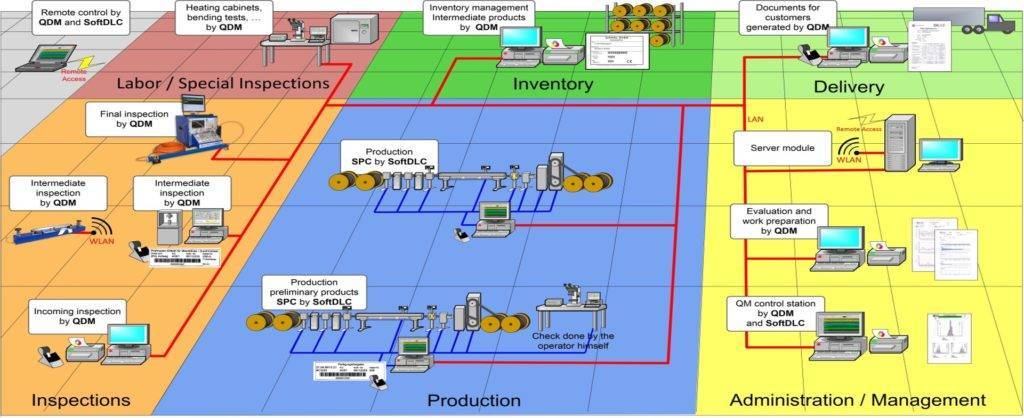

Today, a wide range of inspection technologies are available, and cable manufacturing facilities are covered with multiple measuring devices. All these instruments are very often specific to one particular machine or task, which means that measurements are made in separate and independent “quality islands”. Clearly, maximum benefit from the data generated by all testing and measuring devices is only achievable if such “quality islands” are connected together, allowing to get an overall view of global manufacturing performance.

CIQ 3.0 networks all measuring and testing devices into one common system and stores all the acquired data in a central database. This enables all the entities involved in managing the production processes to have direct access to process and testing data – practically in real time.

The entire manufacturing process will benefit from optimal production control, total quality documentation, reduced planning and testing effort… in short, a coherent, unified system for maximum production efficiency.

- System specifically designed for the cable industry (wire or cable length and time-related)

- Centralized data storage in a unique data format offering global date evaluation capabilities

- Open system (data exchange with various clients and systems such as ERP, MES,…)

- Core functionalities combined with a modular-design providing an efficient and fully customizable system