Automotive

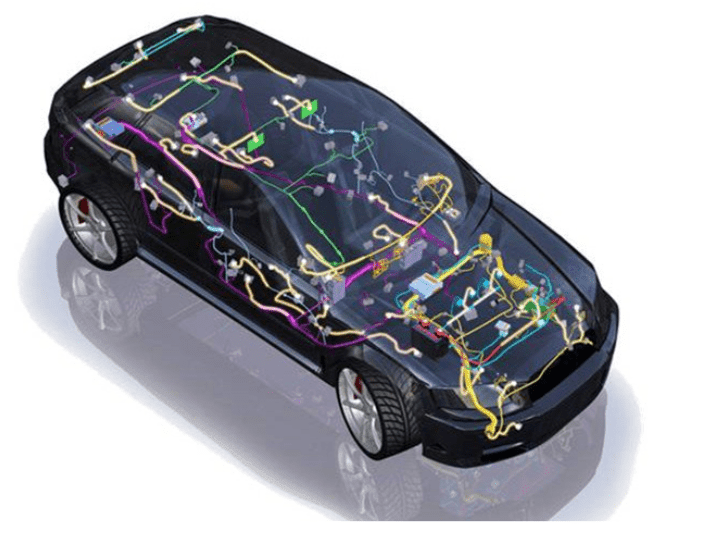

The quantity of cables in cars is continuously increasingly. The length of the cables for power and information transfer in a car can reach several kilometres. As the reference in cable metrology , we ensure that the cables meet the strict quality and safety requirements in this industry

The automotive industry is one of the largest industrial sectors. Since Carl Benz invented the modern automobile, the industry has grown steadily and, above all, rapidly. From a worldwide production of 9,500 cars in 1900, this figure is now more than 10,000 times higher every year.

Aerodynamics, weight, speed and many other factors are perfected day by day. The advent of the electric car has further boosted this industry, and above all has exponentially increased the quantity of cables and wires present in such vehicle.

Up until the 1990s, car electrical systems were rather simple in design. Each function (headlight, heater…) had its own cable and button. The total length of electrical wiring did not exceed 200 meters. Then, in 1989, multiplexing was introduced. This technology enables the same cable to be used for several peripherals installed in the car by using a type of communication system known as a ‘bus’. While this technology theoretically reduces the number of cables, the complexity of on-board equipment (multimedia, navigation system, reversing camera, distance sensors, etc.) has in fact caused the number of cables required to dramatically increase. Today, we’re talking about more than 5 kilometers of cable per vehicle, depending on the complexity. An electric vehicle (EV), for example, uses 1 kilometer just to connect the battery to all the electrical components. In total, this corresponds to around 80 kilograms of copper.

We can seperate 3 different categories of cables in automotive:

- Battery cables used in a variety of vehicles such as cars, trucks, buses, marine, tractors and off-road vehicles and industrial equipment. It is a low-voltage solution for automotive, agricultural and construction electrical connection applications. It is available in both copper and aluminium constructions.

- Mono-core cables used for automotive point-to-point electrical connection and is ideal for general purpose wiring in automobiles, boats, trucks, buses, tractors, trailers and other motor-driven equipment.

- Multi-core cables used for sensor assemblies in passenger cars, trucks, buses, marine equipment, or any vehicle where heat, flexibility and resistance to chemicals and abrasion are required.

In the automotive industry, safety demands that any cable must meet strict quality requirements.

In addition to respecting the required quality, cost is also an essential criterion for ensuring product competitiveness. It is therefore crucial to use automatic, reliable and user-friendly test instruments that allow for traceability and process improvements.

- All

- Communication

- Energy

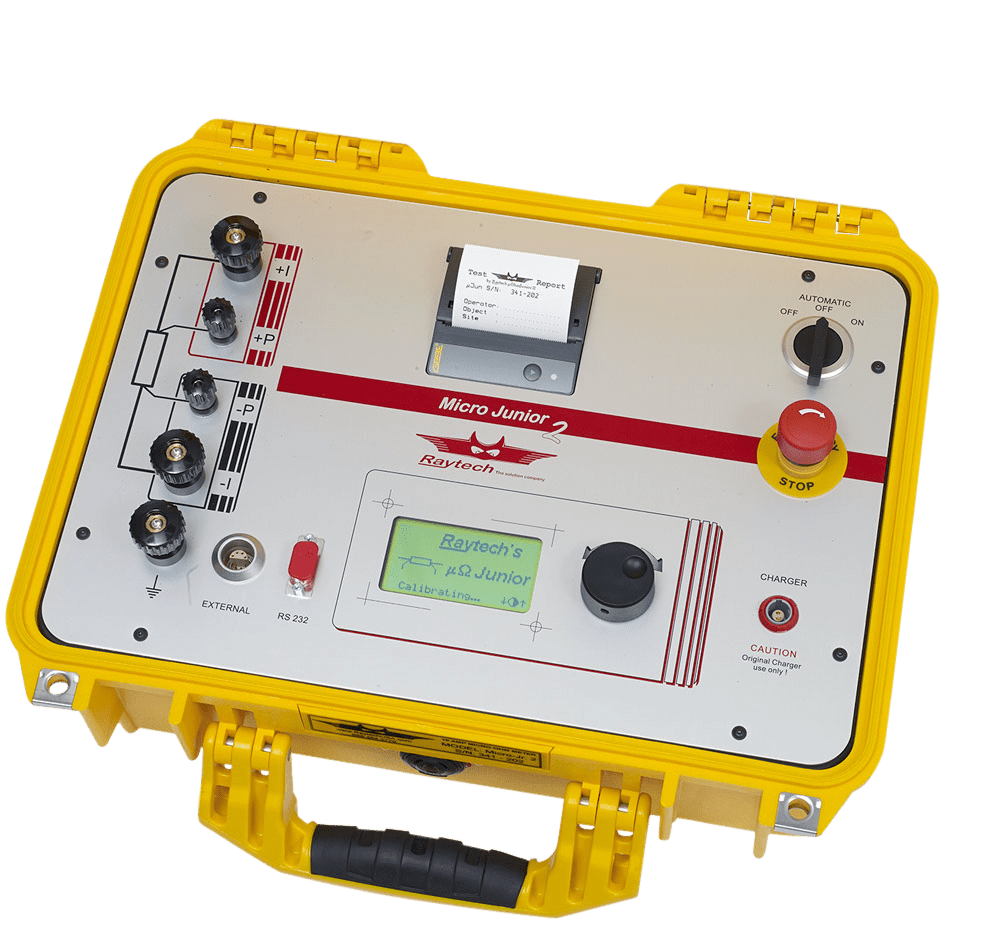

RestTest 50

Energy cables – up to 50 mm2

ResTest 90

Energy cables – up to 1,000 mm2

ResTest 95 WaterBath

NEW – cool your conductor fast!

Cobalt

For HF communication cables

Castor

Single Pair Ethernet (SPE)

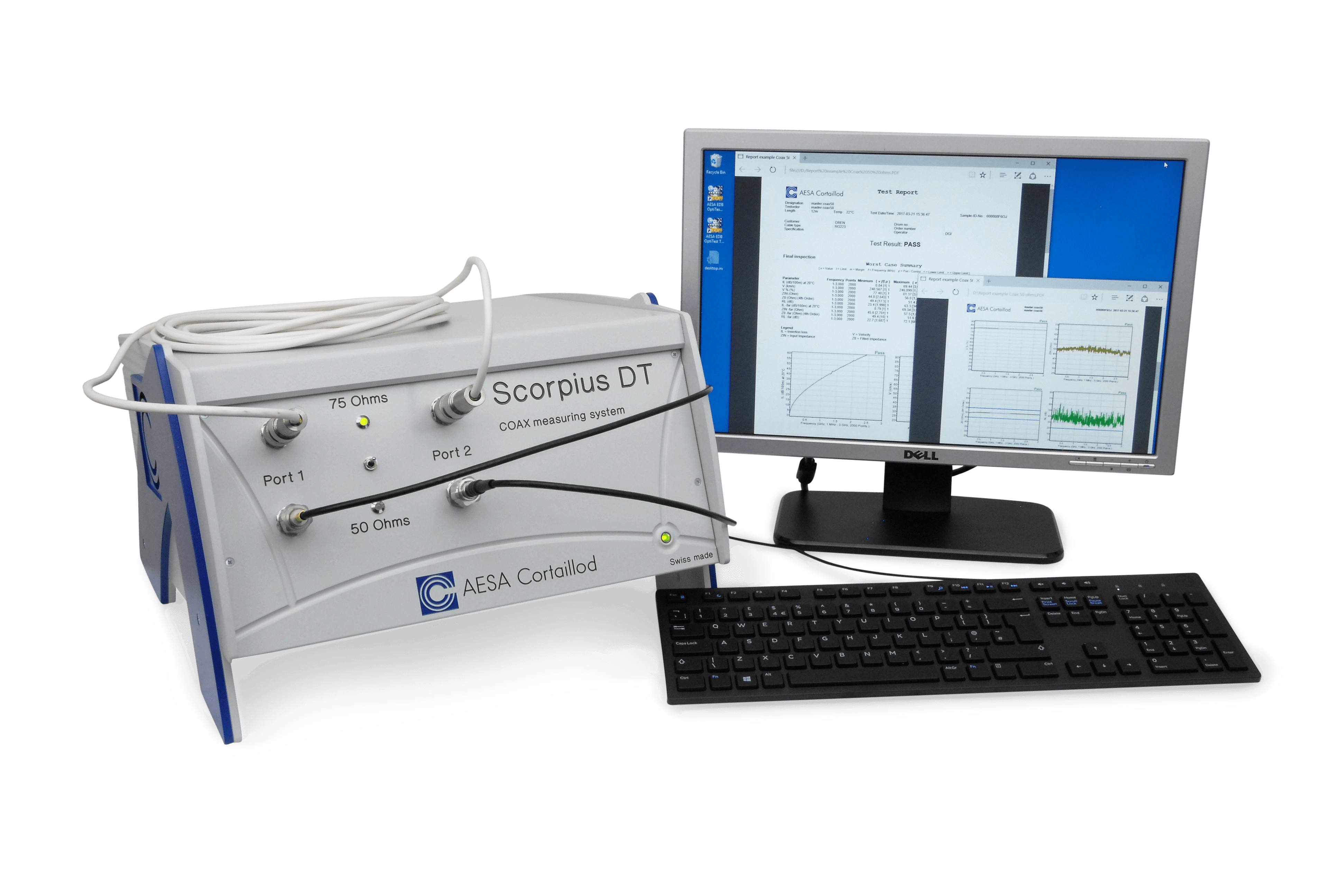

Scorpius

For coaxial cables

EMC measurement

For all types of EMC testing

ResTest Drum

Measures directly on the drum

Testing Laboratory

For automotive cable qualification